咨询服务热线: 0514-87885777

腾达试验仪器厂:

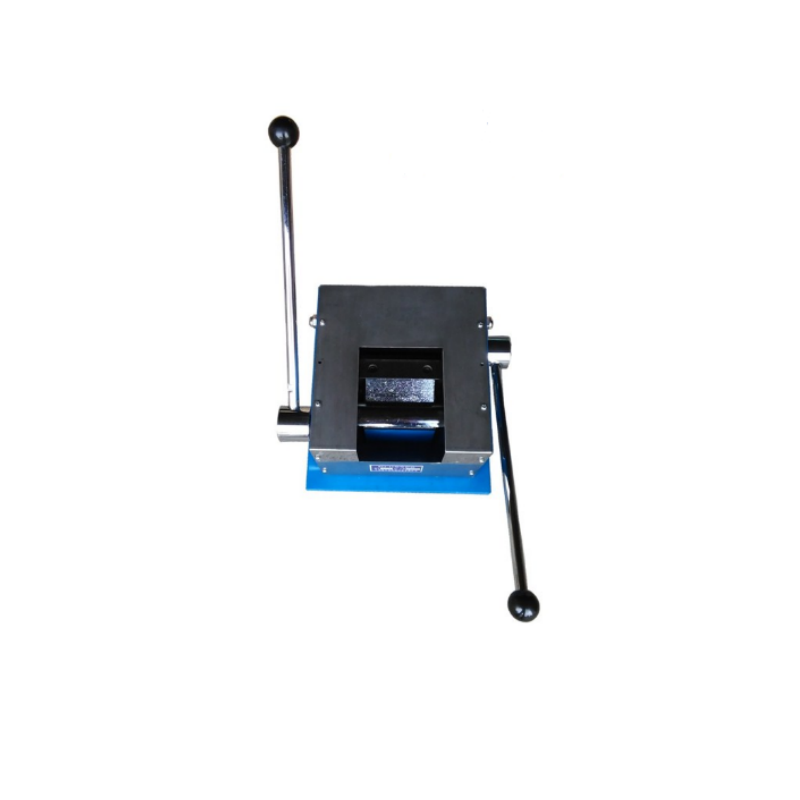

T型弯折机是**检测仪器,用于测试彩色钢板及钢带的涂层以及有关产品涂层的T型弯曲试验。T型弯折机符合**GB/T12754-91标准是测试涂膜柔韧性的一种新机型。该设备符合NCCA《标准“T”弯试验方法》的要求。根据目前彩色钢板,铝板的生产厂家对彩色钢板、铝板的柔韧性-T弯性能进行测试的要求,结合生产实际而精心制造的。

T-bending machine is a testing instrument for testing the coating of colored steel plates and steel strips and the T-bending test of related product coatings.T type bending machine conforms to**GB/T12754-91 standard is a new model to test the flexibility of coating film.This equipment complies with the requirements of the NCCA Standard"T"Bend Test Method.According to the current requirements of color steel plates and aluminum plate manufacturers for testing the flexibility-T bending performance of color steel plates and aluminum plates,they are carefully manufactured in accordance with the actual production.

T型弯折机技术参数:

■一次弯曲角∠45°

■压平机构行程≥10mm

■可试样板厚度:0.5~1.0mm

■重量:75Kg

T-type bending machine technical parameters:

■One-time bending angle∠45°

■Stroke of flattening mechanism≥10mm

■Sample plate thickness:0.5~1.0mm

■Weight:75Kg

T型弯折机操作步骤:

■旋转弯曲杆上的螺丝,压力辊便作用于测试片上,圆轴则在下方,转动弯曲杆,直到其达到仪器右手边的**限位。此运动将引起测试片围绕选定圆轴弯曲。

■弯曲过程需在一个平稳的运动中进行,时间为1~2秒。

■弯曲机构的杆转到左手边的**限处(与黑色旋钮相对)。此动作松开圆柱的贮槽。将所需的圆柱放到槽中,将测试片垂直插入到圆柱和压力辊轴之间(涂层面对着弯曲柱),并推入下端的夹紧装置之间。夹紧单元可以调节,但在此时期,夹装置不应完全锁紧。拉动黑色的旋钮,通过导向辊,和夹紧单元一起滑动插入的测试片,使它的位置对着圆轴。然后完全锁紧黑色的旋钮,确保夹紧单元和测试板固定在此位置。

T-bending machine operation steps:

■Rotate the screw on the bending rod,the pressure roller acts on the test piece,and the round shaft is below.Turn the bending rod until it reaches the**limit on the right hand side of the instrument.This movement will cause the test piece to bend around the selected circular axis.

■The bending process needs to be performed in a stable movement,the time is 1~2 seconds.

■The lever of the bending mechanism is turned to the**limit on the left hand side(as opposed to the black knob).This action releases the cylindrical tank.Place the required cylinder into the groove,insert the test piece vertically between the cylinder and the pressure roller shaft(the coating faces the curved column),and push it between the clamping devices at the lower end.The clamping unit can be adjusted,but the clamping device should not be fully locked during this period.Pull the black knob and slide the inserted test piece with the clamping unit through the guide roller so that its position is facing the round shaft.Then fully tighten the black knob to ensure that the clamping unit and test board are fixed in this position.

T型弯折机功能:

■试验报告:(可根据客户需要)

拉伸:大力、拉伸强度、断裂伸长率、弹性模量等。

弯曲:大力、弯曲强度、挠度、弹性模量等。

压缩:大力、压缩强度、屈服强度、弹性模量等,也可按用户要求的格式对试验报告进行编程和打印;

■限位保护:具有程控和机械两级保护;

■过载保护:当负载超过额定的10%时自动停机;

紧急停机:设有急停开关,用于紧急状态切断整机电源;

自动诊断:系统具有自动诊断功能,定时对测量系统,驱动系统进行过压,过流、超温等到检查,出现异常情况即刻停机;

■实现主机和微机独立操作。

■自动清零:计算机接到试验开始指令,测量系统便自动清零。

■自动返车:自动识别试验断裂后,活动横梁自动高速返回初始位置。

■自动存盘:试验数据和实验条件自动存盘,杜绝因突然断电忘记存盘引起的数据丢失。

■测试过程:试验过程及测量、显示、分析等均由微机完成。

■显示方式:数据和曲线随试验过程动态显示。

■结果再现:试验结果可任意存取,可对数据曲线再分析。

■曲线遍历:试验完成后,可用鼠标找出试验曲线逐点的力值和变形数据,对求取各种材料的试验数据方便实用。

■结果对比:多个试验特性曲线可用不同颜色叠加、再现、放大、呈现一组试样的分析比较;

■曲线选择:可根据需要选择应力应变、力时间、强度时间等曲线进行显示和打印;

■批量试验:对参数相同的试验一次设定后可顺次完成一批试样的试验。

T-bending machine function:

■Test report:(according to customer needs)

Tensile strength:tensile strength,elongation at break,modulus of elasticity,etc.

Bending:strong,bending strength,deflection,elastic modulus,etc.

Compression:vigorous force,compressive strength,yield strength,elastic modulus,etc.The test report can also be programmed and printed in the format required by the user;

■Limit protection:with two levels of program-controlled and mechanical protection;

■Overload protection:when the load exceeds 10%of rated,it will automatically stop;

Emergency stop:equipped with an emergency stop switch,which is used to cut off the power supply of the whole machine in an emergency;

Automatic diagnosis:The system has an automatic diagnosis function.The measuring system and the drive system are regularly checked for over-voltage,over-current,over-temperature,etc.,and immediately stop when abnormal conditions occur;

■Achieve independent operation of host computer and microcomputer.

■Automatic zeroing:The computer receives the test start instruction,and the measurement system automatically resets to zero.

■Automatic return:After the test break is automatically identified,the movable beam automatically returns to the initial position at high speed.

■Automatic saving:The test data and experimental conditions are automatically saved to prevent data loss caused by sudden power failure and forgetting to save.

■Test process:The test process and measurement,display,analysis,etc.are all completed by a computer.

■Display mode:The data and curve are dynamically displayed with the test process.

■Result reproduction:The test results can be accessed arbitrarily,and the data curve can be reanalyzed.

■Curve traversal:After the test is completed,you can use the mouse to find the point-by-point force value and deformation data of the test curve,which is convenient and practical for obtaining the test data of various materials.

■Comparison of results:Multiple test characteristic curves can be superimposed,reproduced,enlarged,and analyzed with a set of samples in different colors;

■Curve selection:the curve of stress-strain,force time,intensity time can be selected for display and printing according to the needs;

■Batch test:After setting the test with the same parameters once,the test of a batch of samples can be completed sequenti

微信扫一扫