咨询服务热线: 0514-87885777

腾达试验仪器厂:

铅笔硬度计是检测仪器,涂膜硬度是涂料制造、涂料使用(涂表)行业进行质量认定的必测指标。铅笔划痕法测试涂膜硬度是八十年代以来被国际普遍采用的测试方法。我国也已在涂料的发展研究和工业生产中推广这种测试方法。本仪器是根据**标准“涂膜硬度铅笔测定法”《GB6379----86》第2 3条手工操作法而设计制造的。仪器即可在实验室使用,也可用也施工现场,并能在任意方向上对涂膜硬度进行检定。

The pencil hardness tester is a testing instrument,and the hardness of the coating film is an indispensable indicator for quality certification in the coatings manufacturing and coatings(painting)industries.The pencil scratch method for testing coating film hardness is a test method generally adopted internationally since the 1980s.China has also promoted this test method in the research and industrial production of coatings.This instrument is designed and manufactured according to the manual method of Article 23 of the**standard"Paint Film Hardness Pencil Method""GB6379----86".The instrument can be used in the laboratory or at the construction site,and the hardness of the coating film can be verified in any direction.

铅笔硬度计结构及工作原理:

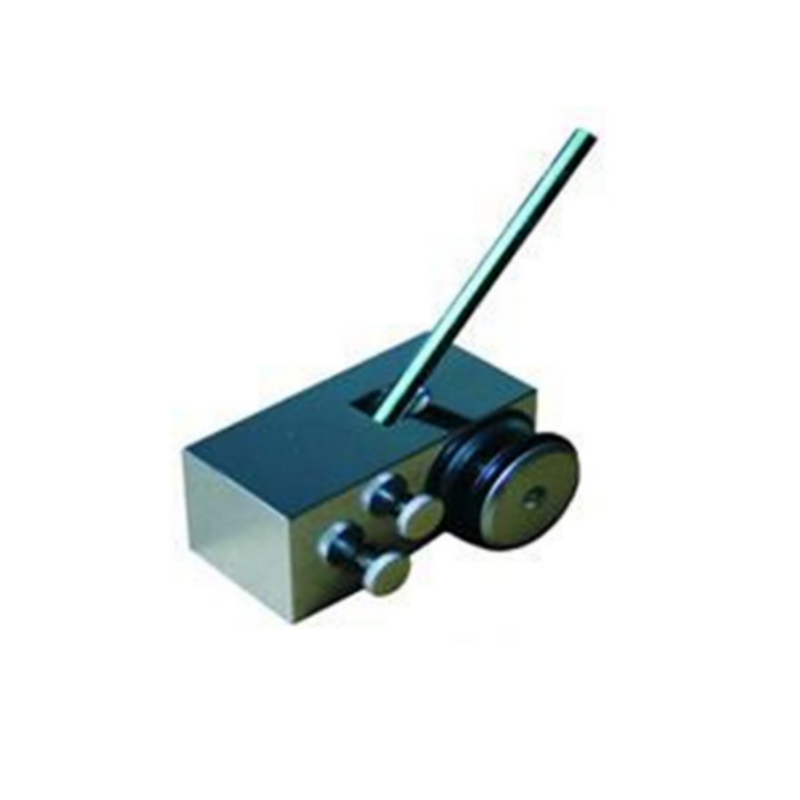

仪器为机械式,三点接触被测表面(二点为轮,一点为铅芯)始终保证铅笔与被测表面形成45°夹角,用于推动仪器运动,即可完成测试过程。

Pencil hardness tester structure and working principle:

The instrument is mechanical,and three points contact the tested surface(two points are the wheel and one point is the lead core).Always ensure that the pencil forms a 45°angle with the measured surface.

铅笔硬度计技术参数:

★笔尖重负:750±5g。

★铅笔规格:6B~HB~6H(13支)。

★重量:1.9Kg。

★外形尺寸:120×75×60mm(长×宽×高)。

★笔尖重负:500±5g。

★铅笔规格:6B~HB~6H(13支)。

★重量:1.6Kg。

★外形尺寸:90×75×60mm(长×宽×高)。

★笔尖重负:1000±5g。

★铅笔规格:6B~HB~6H(13支)。

★重量:2.4Kg。

★外形尺寸:130×75×60mm(长×宽×高)。

Technical parameters of pencil hardness tester:

★Pen tip load:750±5g.

★Pencil specifications:6B~HB~6H(13 pieces).

★Weight:1.9Kg.

★Dimensions:120×75×60mm(length×width×height).

★Pen tip load:500±5g.

★Pencil specifications:6B~HB~6H(13 pieces).

★Weight:1.6Kg.

★Dimensions:90×75×60mm(length×width×height).

★Pen tip load:1000±5g.

★Pencil specifications:6B~HB~6H(13 pieces).

★Weight:2.4Kg.

★Dimensions:130×75×60mm(length×width×height).

铅笔硬度计重量

★笔尖荷重500g的硬度计,没包装前重量为2kg。加上泡沫纸皮等外包装应该是2.5kg重量。

★笔尖荷重750g的硬度计,没包装前重量为2.4kg。加上泡沫纸皮等外包装应该是3kg重量。

★笔尖荷重1000g的硬度计,没包装前重量为2.5kg。加上泡沫纸皮等外包装应该是3kg重量。

Pencil hardness tester weight

★The hardness of the pen tip load is 500g,the weight before packing is 2kg.Plus foam paper skin and other packaging should be 2.5kg weight.

★The hardness of the pen tip is 750g,and the weight is 2.4kg before packaging.Plus foam paper skin and other packaging should be 3kg weight.

★The hardness tester with a tip load of 1000g is 2.5kg before packing.Plus foam paper skin and other packaging should be 3kg weight.

铅笔硬度计操作规程:

A准备

★按GB1727要求准备120*50*(0.2-0.3)平滑马口铁板或按产品规定的底材,制备涂膜。

★用铅笔刀把每支铅笔前端削去木质部分,露出5-6mm柱状笔芯(注意铅笔芯不可松动或削伤铅芯),用手握住铅笔,使铅笔始终与400号砂纸成90°角,在砂纸上摩擦铅芯端面,直到获得一端平滑边缘锐利的笔端为止(边缘要无破碎或缺口)

★把削好的铅笔插入铅笔架上。调整铅笔,使铅笔芯工作端面与砝码心重合(相应铅芯工作端面与铅笔架约25mm),然后用螺钉拧紧,使铅笔位置固定。

★松开夹紧螺母,放入需测定的涂膜试片,然后拧紧螺母,使试片固定。

★松开止动螺钉,调整平衡锤,使工作杆平衡(即使铅笔刚好接触到试片上),然后拧紧止动螺钉,使铅笔芯工作面离开涂膜试片。

★把砝码轻轻放在铅笔架上。

B测试

★松开止动螺钉,使铅笔芯轻轻降下到被测涂膜试片上。

★转动手轮,使涂膜板朝划痕方向移动大约5mm(顺时针转动手轮),并留意观察表面是否划破。

★取下砝码,更换铅笔,旋动试台旋扭,使试验台纵向移动一定距离更换试片划痕位置,重复准备操作后,再做下一次试验,依次用每种型号硬度的铅笔一次犁出五道痕迹。

★从a硬的铅笔开始用此方法,当鉴定五道痕迹中,若有两次或两次以上犁伤膜时,换上一级的铅笔,直到找出五道痕迹中,只有一次犁伤涂膜的铅笔(或没有破坏)。则这一级铅笔的硬度值**代表被测涂膜的硬度。

Pencil hardness tester operating procedures:

A ready

★Prepare 120*50*(0.2-0.3)smooth tinplate according to the requirements of GB1727 or the substrate specified by the product to prepare the coating film.

★Use a pencil sharpener to shave the wooden part of the front end of each pencil to expose a 5-6mm columnar refill(note that the lead cannot be loosened or damage the lead).Hold the pencil with your hand so that the pencil is always at a 90°angle with 400-size sandpaper,Rub the end surface of the lead on the sandpaper until you get a smooth pen with a sharp edge at one end(the edge should be free of cracks or nicks)

★Insert the sharpened pencil into the pencil holder.Adjust the pencil so that the working surface of the pencil lead coincides with the weight center(the corresponding working surface of the lead lead is about 25mm from the pencil holder),and then tighten with a screw to fix the pencil position.

★Loosen the clamping nut,put the coating film test piece to be measured,and then tighten the nut to fix the test piece.

★Loosen the stop screw,adjust the balance weight to balance the work rod(even if the pencil just touches the test piece),and then tighten the stop screw so that the working surface of the pencil lead leaves the test film.

★Put the weight lightly on the pencil holder.

B test

★Loosen the stop screw,and lower the pencil lead onto the test film of the test film.

★Turn the handwheel to move the coating film about 5mm in the direction of the scratch(turn the handwheel clockwise),and pay attention to observe whether the surface is scratched.

★Remove the weight,replace the pencil,rotate the test bench to make the test bench move a certain distance in the longitudinal direction to change the scratch position of the test piece,repeat the preparation operation,and then perform the next test,using each type of pencil in order Five traces were plowed.

★Use this method from a hard pencil.When identifying five traces of plow injury film,if there are two or more plow injury membranes,change the pencil to the next level until you find one of the five traces.Paint the pencil(or not break).Then the hardness value**of this grade pencil represents the hardness of the tested coating film.

微信扫一扫