咨询服务热线: 0514-87885777

腾达试验仪器厂:

一,密封材料表干时间测定器产品简介:

密封材料表干时间测定器是专业检测仪器,用于在规定条件下,将密封胶试样填充到规定形状的模框中,用在试样放置薄膜或指触的方法测量其干燥程度。报告薄膜或手指上无粘附试样所需的时间。符合GB 16776-2005《建筑用硅酮密封胶》、GB/T 13477.5-2002《建筑密封材料试验方法表干时间的测定》标准。

the product introduction:

The sealing material surface dry time measuring device is a professional testing instrument for filling a sealant sample into a mold frame of a prescribed shape under a prescribed condition,and measuring the dryness of the sample by placing a film or a finger touch.Report the time required for the film or finger to have no adherent sample.It complies with GB 16776-2005"Silicone Sealant for Construction"and GB/T 13477.5-2002"Test Method for Measuring Sealing Time of Building Sealing Materials".

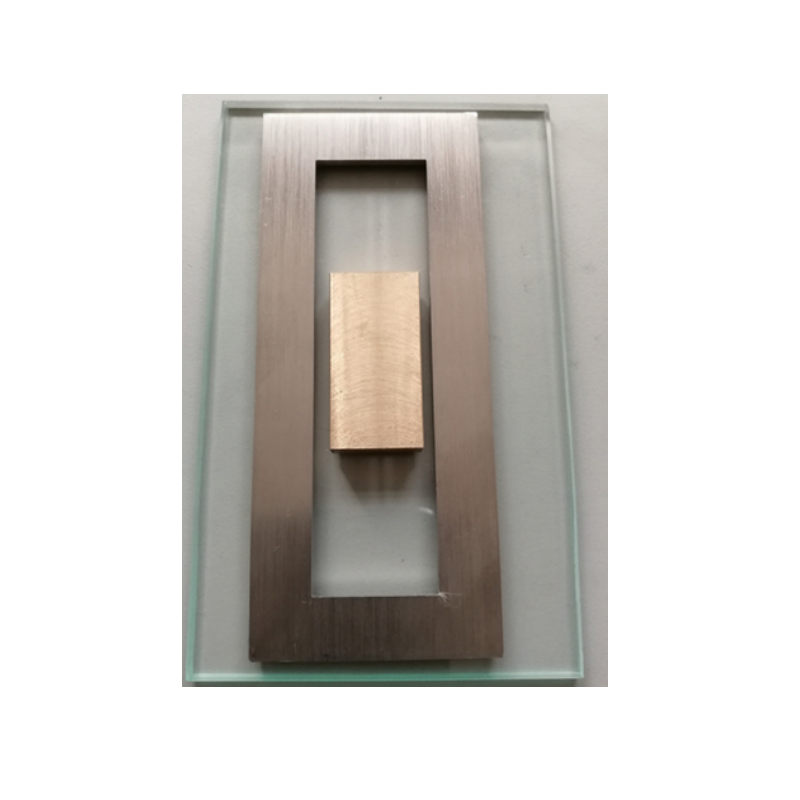

二,密封材料表干时间测定器配置:

♦黄铜板:尺寸19mm×38mm,厚度约6.4mm

♦模框:矩形,用钢或铜制成,内部尺寸25mm×95mm,外形尺寸50mm×120mm,厚度3mm。(需要外加工)

♦玻璃板:尺寸80mm×130mm,厚度5mm

♦聚乙烯薄膜:2张,尺寸25mm×130mm,厚度0.1mm

♦刮刀无水乙醇

Second,the sealing material surface time measuring device configuration:

♦Brass plate:size 19mm×38mm,thickness about 6.4mm

♦Mold frame:rectangular,made of steel or copper,internal dimensions 25mm×95mm,external dimensions 50mm×120mm,thickness 3mm.(requires external processing)

♦Glass plate:size 80mm×130mm,thickness 5mm

♦Polyethylene film:2 sheets,size 25mm×130mm,thickness 0.1mm

♦scraper

三,密封材料表干时间测定器试件的制备:

用丙酮等溶剂清洗模框和玻璃板。将模框居中放置在玻璃板上,用在(23±2)℃下至少放置过24h的试样小心填满模框,勿混入空气。多组分试样在填充前应按生产厂的要求将各组分混合均匀。用刮刀刮平试样,使之厚度均匀。同时制备两个试件。

Third,the preparation of the test piece:

The mold frame and the glass plate are washed with a solvent such as acetone.Place the mold frame on the glass plate and carefully fill the mold frame with a sample that has been placed at least(24±2)°C for 24 hours.Do not mix air.Multi-component samples should be mixed evenly before filling according to the requirements of the manufacturer.Stencil the sample with a spatula to make it uniform in thickness.Two test pieces were prepared at the same time.

四,密封材料表干时间测定器试验方法与步骤:

♦方法A

1,将制备好的试件在标准条件下静置一定的时间

2,然后在试样表面纵向1/2处放置聚乙烯薄膜,薄膜上中心位置加放黄铜板。

3,30s后移去黄铜板,将薄膜以90°角从试样表面在15秒内匀速揭下。

4,相隔适当时间在另外部位重复上述操作,直至无试样粘附在聚乙烯条上为止。

5,记录试件成型后至试样不再粘附在聚乙烯条上所经历的时间

♦方法B

1,将制备好的试件在标准条件下静置一定的时间.

2,然后用无水乙醇擦净手指端部,轻轻接触时间上三个不同部位的试样。

3,相隔适当时间重复上述操作,直至无试样粘附在手指上为止。

4,记录试件成型后至试样不再粘附在手指上所经历的时间

密封材料表干时间测定器实验结果判定

表干时间≤3h,判定为合格

Fourth,experimental methods and steps:

♦Method A

1.The prepared test piece is allowed to stand under standard conditions for a certain period of time.

2.Then,a polyethylene film is placed at a longitudinal direction of the surface of the sample,and a brass plate is placed on the center of the film.

After 3,30 s,the brass plate was removed and the film was peeled off at a constant angle of 15 seconds from the surface of the sample within 15 seconds.

4.Repeat the above procedure at another location at appropriate intervals until no sample adheres to the polyethylene strip.

5,record the time after the test piece is formed until the sample no longer adheres to the polyethylene strip

♦Method B

1.The prepared test piece is allowed to stand under standard conditions for a certain period of time.

2,then wipe the end of the finger with absolute ethanol,gently touch the sample of the three different parts of the time.

3.Repeat the above procedure at appropriate intervals until no sample adheres to the finger.

4.Record the time elapsed after the test piece is formed until the sample no longer adheres to the finger.

Determination of experimental results of sealing material surface dry time tester

Dry time≤3h,judged to be qualified。

五,密封材料表干时间测定器试验过程注意事项:

♦表干时间的数值修约

♦表干时间少于30min时,精确至5min;

♦表干时间在30min至1h之间时,精确至10min;

♦表干时间在1h至3h之间时,精确至30min;

♦表干时间超过3h时,精确至1h。

Five,the test process notes:

♦Numerical repair of the dry time

♦When the dry time is less than 30min,the accuracy is 5min;

♦When the surface drying time is between 30min and 1h,it is accurate to 10min;

♦When the surface drying time is between 1h and 3h,it is accurate to 30min;

♦When the surface dry time exceeds 3h,it is accurate to 1h.

微信扫一扫